Safety First: Health and Safety Considerations in AC Jobs

As an AC technician, it is essential to be aware of these risks and take the necessary precautions to ensure a safe working environment for yourself and your colleagues.

Importance of Health and Safety in AC Jobs

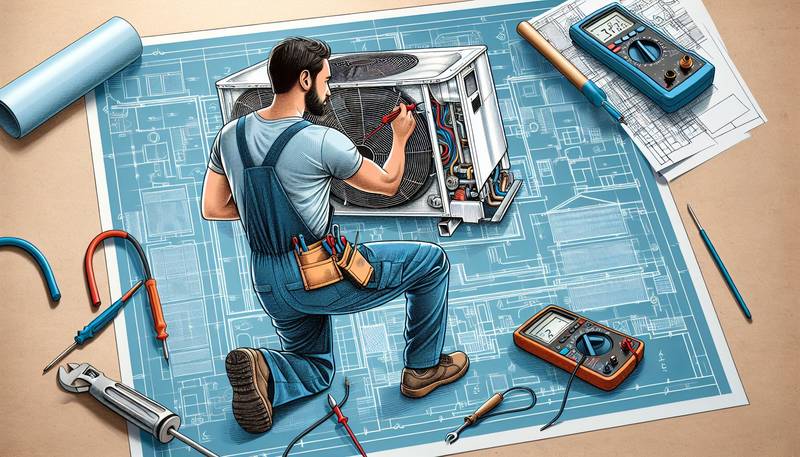

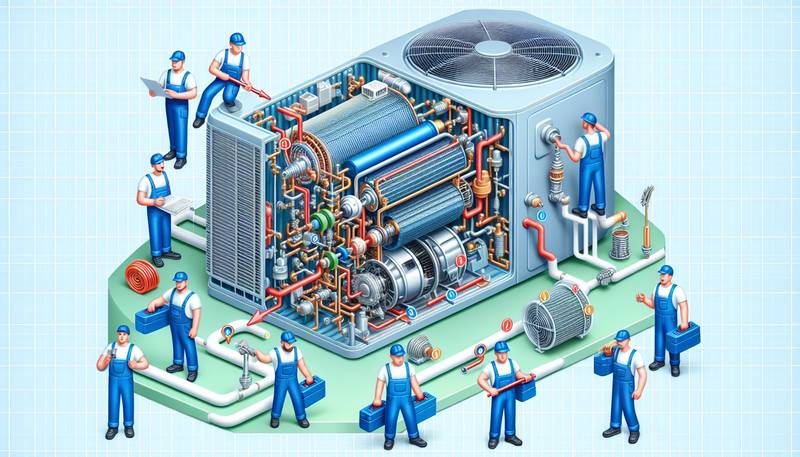

When working in the AC industry, technicians are often exposed to hazardous materials such as refrigerants, electrical components, and moving parts of machinery. Without proper precautions, these materials can pose a serious threat to the health and safety of workers. In addition, the nature of the job requires technicians to work in confined spaces, at heights, and in extreme temperatures, increasing the risk of accidents and injuries.

Ensuring health and safety in AC jobs is not only a legal requirement but also a moral obligation. Employers have a duty to provide a safe working environment for their employees, and employees have a responsibility to adhere to safety guidelines and procedures to protect themselves and their colleagues. By prioritizing health and safety in AC jobs, technicians can reduce the risk of accidents, injuries, and long-term health issues.

Common Health and Safety Risks in AC Jobs

There are several common health and safety risks that AC technicians may encounter in their line of work. These include:

- Exposure to hazardous materials such as refrigerants, which can cause skin irritation, respiratory issues, and in severe cases, chemical burns.

- Electrical hazards from working with live wires and high-voltage equipment, which can lead to electric shocks, burns, and even electrocution.

- Moving parts of machinery, such as fans and belts, which can cause lacerations, crush injuries, and amputations if not handled properly.

- Working in confined spaces, which can result in asphyxiation, heat exhaustion, and other health risks due to poor ventilation and limited access.

- Climbing ladders and working at heights, which can increase the risk of falls, fractures, and other injuries if proper fall protection measures are not in place.

By being aware of these risks and taking proactive measures to mitigate them, AC technicians can minimize the likelihood of accidents and injuries in the workplace.

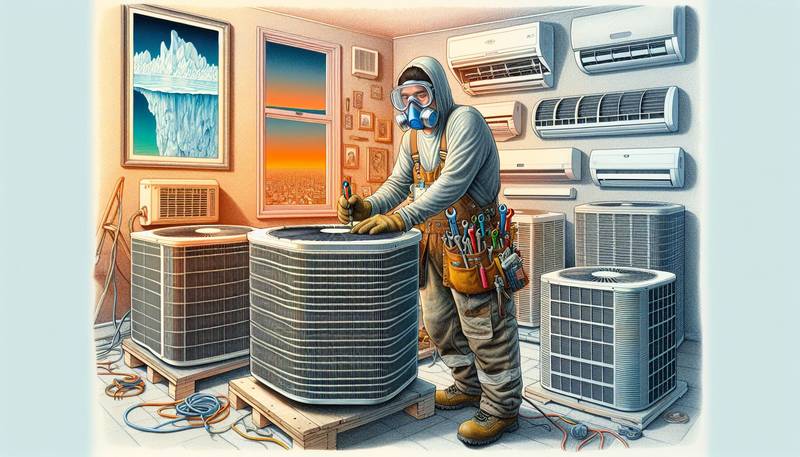

Health and Safety Precautions in AC Jobs

To ensure health and safety in AC jobs, technicians should adhere to the following precautions:

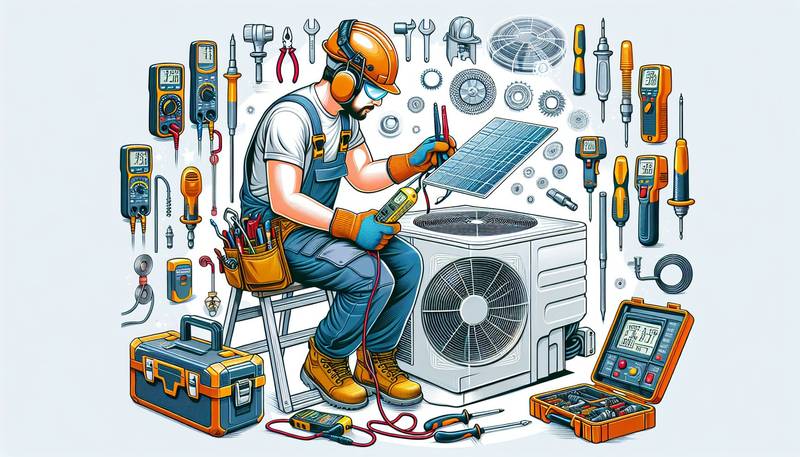

- Use personal protective equipment (PPE) such as gloves, safety goggles, and respirators to protect against hazardous materials and prevent injuries.

- Follow proper handling procedures for refrigerants and other chemicals, including using approved containers, avoiding skin contact, and ensuring proper ventilation.

- Shut off power sources and follow lockout/tagout procedures when working on electrical components to prevent electric shocks and other hazards.

- Inspect machinery and equipment regularly for signs of wear and tear, and perform maintenance as needed to prevent accidents and malfunctions.

- Receive training on working in confined spaces, climbing ladders, and using fall protection equipment to reduce the risk of accidents and injuries.

- Stay hydrated, take breaks as needed, and avoid working in extreme temperatures for prolonged periods to prevent heat-related illnesses and exhaustion.

By following these precautions and staying informed about health and safety guidelines in the AC industry, technicians can create a safer working environment for themselves and their colleagues.

Conclusion

Health and safety considerations are paramount in AC jobs due to the unique risks and hazards that technicians face on a daily basis. By prioritizing health and safety, following proper precautions, and staying informed about industry guidelines, technicians can protect themselves from accidents, injuries, and long-term health issues. Ultimately, safety should always come first in AC jobs to ensure a healthy and productive work environment for all employees.